On modifying my Classic Moths Ive rebuilt decks, rebuilt daggerboard trunks, added buoyancy tanks, glassed interiors, but Ive never grafted a new bottom onto an existing Moth - performing a bottom-ectomy so to speak. British Mad Mothist, Jim Champ, former Cherub sailor, dinghy historian, amateur dinghy designer, current International Canoe sailor, and webmaster of the International Canoe website is doing just that to a fiberglass Skol he purchased.

Ill let Jim explain his project in his own words.

Some photos...

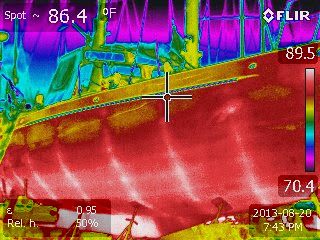

Looks like Jim was able to cold mold over two stringers per side as well as the topside stringer junction.

Finished hull. The Skol featured a self-draining hull. George A, fellow Classic Moth bloggist over at Mid-Atlantic Musings, has also deconstructed a Skol back to a bare hull. Click here to read about his Skol project.

Jim adds the history of the Skol in the comments section which Ive dragged to the main post.

Read More..

Ill let Jim explain his project in his own words.

"The back story is I picked up this 1970ish Skol Int. Moth because I needed something to sail while a health problem was stopping me sailing my Int Canoe in most conditions, and besides, Id always fancied one. The fact that I am now about 5 stone too heavy even for a vintage Moth didnt deter me.

Anyway, the boat came out of someones garage roof, and I completely failed to spot, under the layers of dust, that at some stage the boat had been sliced off at the waterline and been given a new wood bottom, replacing the original glass. This was no problem until after a seasons use it became apparent that the wood bottom had been allowed to rot back in the day, and some crucial bits were now leaking badly as the water had re-penetrated.

So I ended up cutting off the wood bottom, and Im now building a new one, and learning about cold moulding while I am at it. Shape wise its roughly based on a Cherub I drew in about 1974 but could never afford to build.

What have I learned from this project? Not to be afraid of cold moulding, and when you do it use plenty of strips. I originally was trying to use quite large panels in order to minimize the number of accurate edges I had to cut, but actually getting the sides of the strips accurate is surprisingly easy given a small sharp plane and a block and sandpaper. Its definitely right to have too many strips rather than too few. Getting the length right on a very 3d boat, on the other hand was a nightmare, but in any rational new build that wouldnt be an issue. 2mm ply was definitely much easier than 2.5mm veneer, having tried both, but if you use ply you cant varnish because the smart money is youll go through the outer layer in some (or in my case, many) places when fairing up.

I did the boat partly in 2 * 3mm and partly in 3 * 2mm. The junction between the two was something of a pain and in any case I carried 3mm too far forward. The last bit of 3mm was definitely excessively 3d. Im sure the boat is somewhat asymmettric in that area because with the panels at 45/45 ish, bending the last bit was problematic. The first layer has a much bigger impact on final shape than subsequent ones, and in the transition on one side the first skin was 2mm and the other 3mm. It would probably have been better to suffer the horrendous cost of the 2mm ply and done the whole boat in that. If I were doing a new boat it would be 2 * 2mm ply all over with a glass skin inside and out, uprating the inner skin appreciably in the slamming area round the bow by adding inner glass over skin and stringers, not under stringers.

This was the first project I used a router on which was interesting. Vision really was a major problem, I guess my shop isnt that well lit because I found it really hard to see what the cutting edge was doing. For a long accurate cut to put a rabett in the glass topside (ouch, terrible thing to do to a cutting tool) I stapled a batten as a guide right along the boat and that was a major win. The other thing that helped with a router was to get a marker pen and colour the area I wanted to remove, which made it soo much easier to be confident about what I was doing. I still had a few slips in the wrong places though.

Some photos...

Looks like Jim was able to cold mold over two stringers per side as well as the topside stringer junction.

Finished hull. The Skol featured a self-draining hull. George A, fellow Classic Moth bloggist over at Mid-Atlantic Musings, has also deconstructed a Skol back to a bare hull. Click here to read about his Skol project.

Jim adds the history of the Skol in the comments section which Ive dragged to the main post.

"From what I can make out there seem to have been 4 Skol [models].

Mk 1 may have just been 3 prototypes, which look as if they had unstayed masts and a fair gunwale line.

George A.s boat is a Mk 2. The 1969 Moth yearbook said production was planned for two versions, a SL and regate version. The SL was to have a daggerboard and was the lighter built. The yearbook also says [it sported] an unstayed mast. I think in practice many were built with stayed rigs. They seem to have had false floors and stern tanks, at least some with drains through the stern tank. The actual production detail may have varied, but all had the little extra piece at max beam [hiking winglets].

Mine started life as a Skol Mk 3. She has a fair gunwale line, an open stern and a deck stepped mast. The shrouds were supported by glassed in alloy tubes down to the base of the mast foot.